Problem

Synthetic bone is used to replace human bone in many parts of the body. Its most popular application is in hip replacement operations, but it may also be used in the skull, knee, jaw, and other bony areas. All synthetic bone materials are sold by the manufacturers as two components, one in powdered form and one in liquid form, which are mixed together to initially form a viscous material which eventually cures to a rigid final material. The consistency of the viscous material formed on initial mixing, the time available for working the material into its final shape, the time required for final cure, and the rigidity of the final cured material are all important properties that need to be optimized for different endues situations. For example, before curing, the synthetic base material for cranium repair applications needs to be very pourable, while a more dough-like consistency is best for hip replacement work. Hence,manufacturers of these materials need rapid tests for evaluating different synthetic bone formulations. In the past, viscometers and rheometers in the flow mode were used to obtain this information. However, the results were generally poor because the continuous shearing motion during the measurement actually inhibited cure, in effect breaking bonds as the curing reaction made them.

Solution

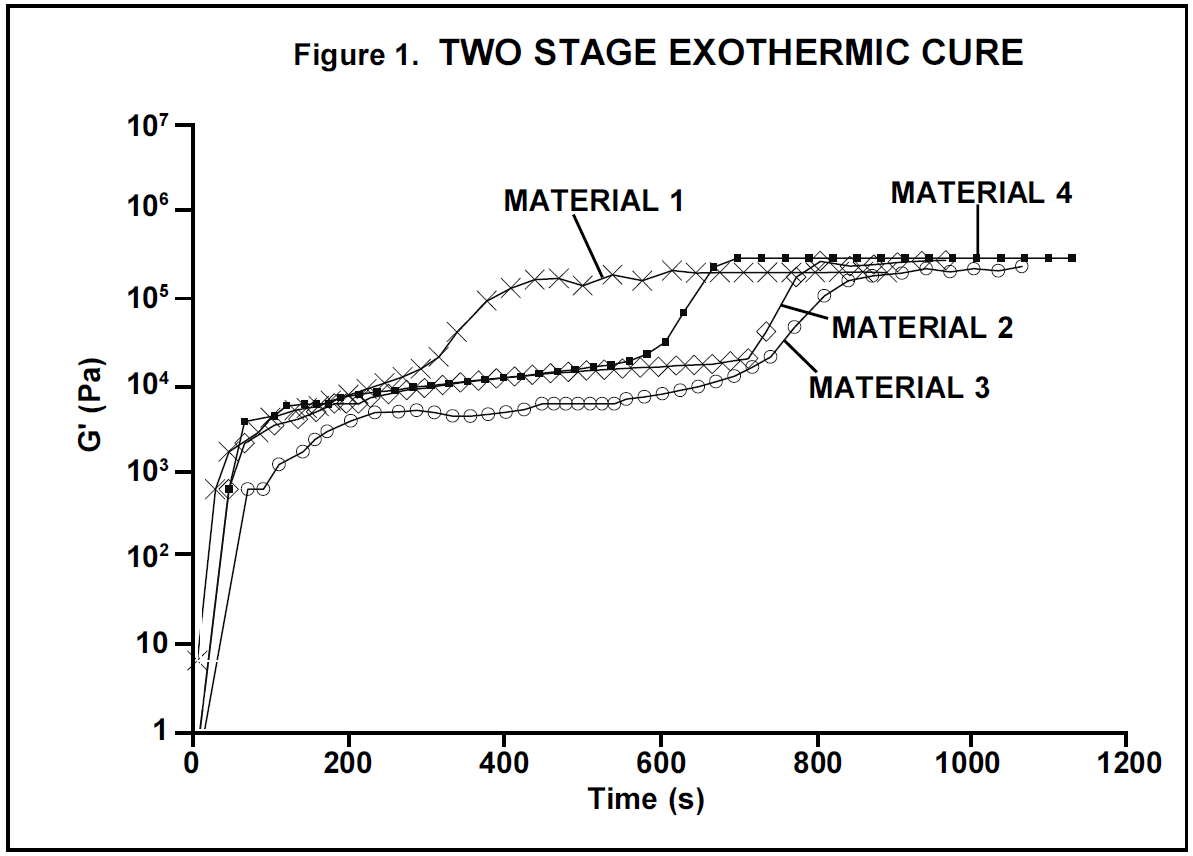

A controlled stress rheometer using an oscillation mode of measurement provides a better method for evaluating these materials. Oscillation works because the materials structure can be evaluated without changing it or influencing the curing process. Figure 1 shows the comparative results for several artificial hip formulations evaluated with time after mixing at 25°C. The angular displacement during oscillation was 1x10-4 radians (less than 0.006°). The G'' results shown here are a measure of the energy a material can store and increase with increasing structure. Other parameters such as G"(loss modulus), h'' (viscosity) and tan d are also produced from the same experiment and are available for further evaluation if required.

The results for all three materials show four key areas of interest:

l Dough formation: G'' rises sharply in roughly a linear fashion when the two components are initially mixed to form the dough. The duration of this sharp increase in G'' gives an objective measurement of the “dough time” for each material. The magnitude of G'' also gives an indication of how firm the dough is. Most of these materials have dough times of around 100 seconds. Material 3 shows the longest dough time of 188 seconds.

l Work time: Once a dough is formed, the increase in G'' slows down considerably. Ideally the dough should maintain a constant consistency for sufficient time to allow the surgeon to pack it into the desired area. These results show that Material 3 and Material 2 have the longest work times. Material 1 has the shortest work time and shows a considerable change in structure during that time.

l Cure time: The second rise in G'' represents the curing time and generally takes a shorter time than the work time. Materials 2 & 4 in this case cure faster from dough to final bone than Materials 1 & 3.

l Final cured bone: The end of cure is signified by G'' reaching a plateau. Figure 1 illustrates that all of these materials achieve a similar final structure. However, the scale is logrithmic and the actual modulus (stiffness) of the cured Material 4 is 75% greater than that for Material 1.